Cleanroom Garments

Our Cleanroom items are Made in the USA

Capabilities & Options

X-Static

- A silver based microfiber

- The natural approach to antimicrobial protection

- Anti-static protection

- Extremely conductive

- Static Decay: The manufacturer suggests t this fiber should remain conductive past 200 washes

Beltron & Nega-Stat

- Excellent static control, lending to dust free garments

- Level of conductivity is dependent on the test method

- Very resistant to static decay

Resistat

- Slightly less conductive than X-Static

- Will definitely last past 200 washings

Want to know more?

We would love to hear more about your project. Straus can use many different fibers to create fabrics t can go toward many different applications. W is yours? Let’s talk.

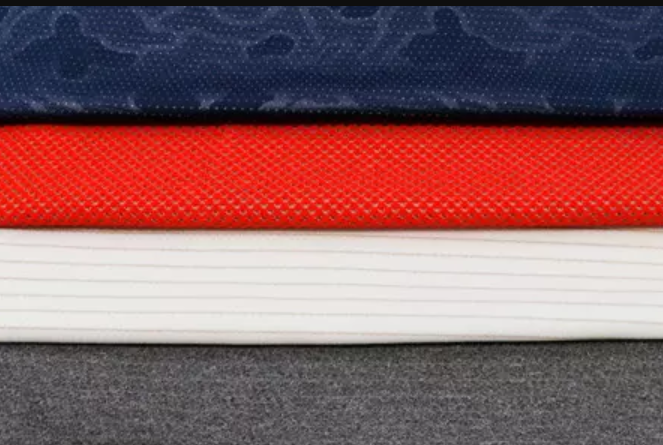

Most often used materials for our Cleanroom Garments

We have developed many fabrics primarily for the Cleanroom industry by blending conductive fibers with other yarns.

We offer four types of conductive fibers:

- X-Static

- Beltron

- Resistat

- Nega-Stat

Textured Poly is highly abrasion resistant, comfortable, and color fast.

Features of Textured Poly

- Strong fiber with good abrasion resistance

- Resistance to wrinkling

- Low moisture regain

- High degree of wickability

- Excellent launderability

- Cost effective

Ultimate Protection, Control and Comfort

Elevate cleanroom standards with our advanced garments integrating X-Static for antimicrobial protection, Beltran & Nega-Stat for superior electrostatic discharge control, and Resistat for a low-resistance path. These technologies collectively ensure a sterile environment, safeguard against ESD, and provide durability for extended wear, setting a new benchmark in cleanroom apparel.